Keeping track of your equipment and maintaining it up to the standard can seem daunting and time-consuming. It’s essential to maintain it so it reaches its full potential and saves you time and money. It also ensures that the machine operates safely, and employees can be safe as well.

It’s easy to neglect the equipment maintenance and let it look after itself. And once it’s worn out, broken, or discarded, you replace it with a new one. Regular maintenance and spending time on equipment will benefit you in many ways.

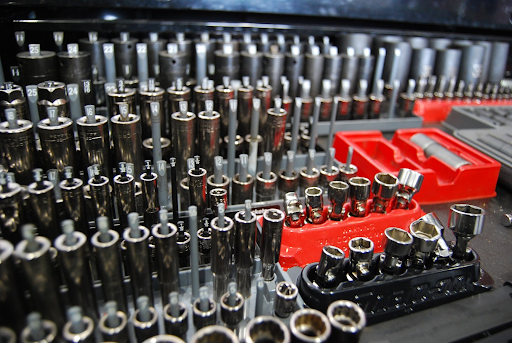

Here is a checklist of tasks that can help you maintain any equipment in top condition.

Use the Correct Equipment

You need to use the right type of equipment for every task. It will help avoid unnecessary wear and tear on machinery and assist them in completing the job in the best way possible.

You can discuss with your suppliers to buy the right Industrial Washers for equipment. Also, look for specific designs and sizes that cater to your needs.

Know the Machine Well

Before using a piece of equipment, you and all the other operators need to know how it works and what it is for. You can carry out a test run if possible.

Be aware of things like the age of the equipment, expected life span, warranty information, and any issues and fixes. It will help ensure that you use it in the correct way to prevent breakages and for safety purposes as well. Only buy quality equipment lime Ultratech Titan that can last you for a longer time.

Perform Regular Inspection

If you perform inspections on your equipment, it can help you point out inconsistencies and issues that need to be fixed right away. It can help in early repair before the issue gets worse or it becomes unsafe for the employees.

Depending upon the nature of the equipment, it might be necessary to get it thoroughly examined by a qualified engineer. These regular inspections can be advised by your supplier or manufacturer.

Carry Out Regular Maintenance

When something goes wrong, it is imperative to get it fixed quickly and correctly. Regular servicing can help avoid unnecessary large outlays.

It is important to create a maintenance schedule to help keep track of parts of every piece of equipment. It can also help control regular inspections.

Clean After Use

Make sure to clean the equipment after use, especially those kinds of equipment that are used for concrete or waste. Regular cleaning will help prevent the build-up of excess in moving parts which can otherwise cause breakage or loss of movement.

Employees need to give a quick rinse down at the end of the shift. Removing the waste can help save a lot of time for the next day.

Get the Parts Repaired

When the equipment doesn’t work quite as well, you may be tempted to go with replacing it as it is an easy option. However, it’s best to go with repair and refurbishment services to get it back in top form.

It will often include repairing any breaks, switching any replaceable parts, a clean-up, and repainting to ensure that it is safe and compliant.